-

RitaThe tricone bit quality is good

RitaThe tricone bit quality is good -

Guramyour bit retrived from the hole ,just let you i am pressed , it performed well .And retrieved bit is like new .

Guramyour bit retrived from the hole ,just let you i am pressed , it performed well .And retrieved bit is like new .

Oil Cutting Drill Bit 6-1/2 Inch PDC Rock Bit Of Sintered Diamond Drill Bits

| Type | Oil And Gas Drill Bits | Use | Oil ,gas ,minig ,drilling |

|---|---|---|---|

| Material | Diamond ,Alloy Steel ,Tungston Carbide | Machine Type | Drilling Tool |

| Processing Type | Forging ,Casting | Application | Rock Drill Of Oil ,mining ,gas |

| Size | 6-1/2"(165.1mm) | Color | Customer Requirement |

| Advantage | High-efficiency , High Strength | Cutter Diameter | 16mm |

| Usage | Oil ,mining ,gas | Blades | 6 Blades |

| Market | Global | Packing | Wooden Box Or Steel Box |

| Name | Oil Well Drilling Pdc Drill Bit | Rock Formation | F<8 |

| Nozzles | 3 | Cutters | Polycrystalline Diamond Compact (PDC) |

| Type | Diamond Drill Bit | Surface Treatment | PDC Insert |

| Highlight | Sintered Diamond PDC Rock Bit,Oil Cutting PDC Rock Bit,Sintered Diamond Drill Bits |

||

Oil Cutting Drill Bit 6-1/2 Inch PDC Rock Bit Of Sintered Diamond Drill Bit

1 . Descriptions:

Polycrystalline diamond compacts PDC bit in the Oil and Gas Industry get their name from the polycrystalline diamond compacts used for their cutting structure. A PDC bit is a drill bit fitted with industrial diamond cutters instead of hardened metal teeth.

According to the International Association of Drilling Contractors (IADC), the Fixed-cutter of PDC Drill bit classification composed of four characters that designate:

- PDC Drill Bit Body material

- PDC Drill Bit Cutter density

- PDC Drill Bit Cutter size or type

- PDC Drill Bit profile

All of our Drill bits are fit for API standard and used in the drilling Industry.

The PDC drill bits size 3~22inch with 3~9Blades are available. And different classification cutter are optional according to your budget .

2. Specification:

| SPECIFICATION | |

| Size : | 6 -1/2" (165.1mm) |

| Drill Body Type : | Steel Body |

| Blades Quantity : | 6 |

| Nozzles Quantity : | 3 |

| API Connection (in) : | 3 -1/2" REG |

| Gauge Length (In): | 3 |

| OPERATIONAL PARAMETERS | |

| Weight on Bit (KN): | 9-67 kN |

| RPM Range(Rotary): | 60-DHM |

| Flow Rate(lps): | 11-17 LPS |

| Make-Up Torque(KN): | 9-13 KN.M |

3 . PDC Drill Bit profile

![]()

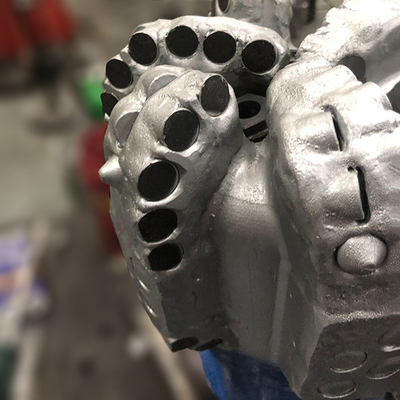

4 . PDC Drill Bit PDC Cutters

Polycrystalline Diamond Composite (PDC) cutters are the main point of contact for a drill bit. PDC bits remove the rock mainly by shearing.

The PDC cutters are exposed to a lot of heating and cooling down the well, a very challenging environment.

PDC cutters that have lower thermal degradation and more thermal stability generally achieve higher ROP and increased wear resistance. So, optimizing the cutter is important.

![]()

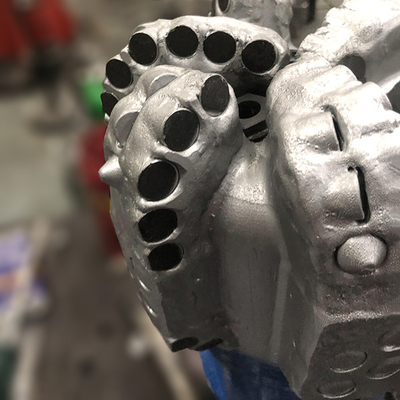

5. PDC Drill Bit Nozzles

PDC Drill bit nozzles help clear the cutting area and cool the Polycrystalline Diamond Composite (PDC) cutters.

Effective placement of these nozzles along with the angle they are set at plays a critical role on how efficient the drill bit performs.

Fluid channels also complement nozzle placement to improve the clearing of cuttings.

![]()

6. Steel Body PDC Bits

Steel body of PDC Drill bit is the opposite of matrix body. It can of withstanding high impact loads, but is softer and lacks protective features. The strength and ductility of steel give steel-bit bodies high impact resistance.

Steel bodies are considerably stronger than matrix bodies.

A beneficial feature of steel bits is that they can easily be rebuilt a number of times because worn or damaged cutters can be replaced rather easily. This is a particular advantage for operators in low-cost drilling environments.

Polycrystalline diamond compact (PDC) drill bits are different than roller cones in that they are one piece bodies with no moving parts. The fixed-cutters shred the rock, so the bit is able to operate with higher rotation speeds more efficiently in consolidated formations.